Not New Technology. A filter-less, high-speed centrifuge for diesel, natural gas, or gasoline engines.

THE LEADERS IN MAKING OIL FILTERING SIMPLE

10 Benefits we can list for using an oil centrifuge.

Can you name 1 for using your filter?

1. Cleaner oil, GUARANTEED

2. 30-50% longer oil life

3. Longer service intervals

4. Reduces engine wear

5. Long-term preventative maintenance

6. Reduced maintenance costs… Cut oil changes by 33% how much do you save?

7. Cuts waste disposal costs

8. Supports engine technology for the reduction of exhaust emissions.

9. Reduces total cost of ownership

10. Helps ensure clean combustion and fuel efficiency.

Why Paper Filters?

Are you are protecting your expensive engines with a $25 paper filter? Then paying again to dispose of the filters?

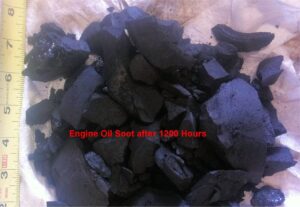

The oil centrifuge uses engine oil pressure to spin the rotor. This proven record of soot removal will extend life of wear parts as well as extend oil change intervals. No filter elements to stock or dispose.

Why an Oil Centrifuge?

Standard 40-micron, full-flow filters will not remove all of the carbon soot particles. They only keep it from circulating in the system.

The centrifuge will, remove, from the oil stream, more of the engine-killing soot. Only the centrifuge is that efficient all the time! No by-pass filter matches the efficiency of the centrifuge. And we can prove it.

Extend oil change intervals 30-50% more depending on engine, age, type of service, and oil quality.

Improve engine efficiency. Tests validate a decrease in fuel consumption by 2-3% based on the studies of the University of Leeds and the American Society of Mechanical Engineers (ASME).

Reduce the need for replacement of high-wear parts.

ROI for marine diesel installations generally 6-12 months depending on engine age and operation.

Recent Comments