Dieselcraft is the leader with over 50 years experience in the design and manufacture of centrifuges for the industrial, commercial, agricultural and marine industry.

The new bypass filter from Dieselcraft can protect an engine up to 25 times cheaper than the competition.

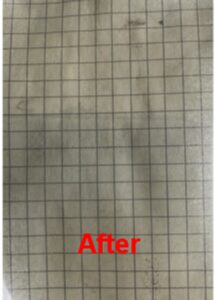

Here is engine oil on a test paper before a centrifuge install and after centrifuge installation.

How to protect your engine from dangerous contaminants without relying on OEM filters.

One current customer started installing centrifuges in 2017, to date they have used 19,000 LESS GALLONS OF OIL.

Here are 12 key benefits of using an oil centrifuge, like Dieselcraft over traditional filters:

- Extended Oil Life: Removes contaminants more effectively, allowing for longer intervals between oil changes (up to 30% longer).

- Reduced Downtime: Minimizes the frequency of oil changes and filter replacements, increasing operational uptime.

- Cost Savings on Filters: Eliminates recurring expenses associated with disposable filters.

- No Flow Restriction: Does not restrict oil flow or affect oil pressure, unlike paper filters which can clog.

- Enhanced Engine Protection: Captures finer contaminants, reducing engine wear and extending overhaul intervals.

- Improved Filtration Efficiency: Spins out particles down to a much smaller size than paper or spin-on filters.

- Reduced Waste: No need to dispose of used filter elements, making it more environmentally friendly.

- Lower Disposal Costs: Reduces costs associated with disposing of traditional filters.

- Lower Operating Costs: Decreases overall maintenance and oil costs over time.

- Greater Reliability for Critical Equipment: Ideal for protecting high-value, mission-critical engines.

- Easy Installation: Designed as a plug-and-play solution that integrates easily with existing engine systems.

- Consistent Performance: Delivers continuous, high-level filtration without the risk of clogging.

In comparison, a traditional $25 paper filter might only capture larger particles and need frequent replacement, offering limited protection to high-value engines.

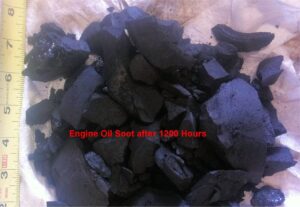

Driven by engine oil pressure the centrifuge works by applying centrifugal force on the soot, and pulls it out of the oil based on weight down to less than 2 micron. Where your filter only holds the soot 25 micron and larger from circulating.

Using a $25 paper filter on a high-value, mission-critical engine, like one worth $1 million, may seem economical upfront but can lead to significant inefficiencies and higher costs in the long run. Let’s break down the math and potential Return on Investment (ROI) of upgrading to a higher-efficiency filtration system like a Dieselcraft centrifuge.

Annual Oil Change Costs with Traditional Paper Filters:

- Cost per Oil Change: $3,000

- Frequency: 4 changes per year

- Annual Cost: 4 x $3,000 = $12,000

This cost covers routine oil changes needed to maintain engine cleanliness

If your oil change cost you $3,000 each and you do four changes per year that is $12,000 based on 1,000 hour changes. Now extend oil life to 1500 hours and changes are reduced to 2.6 changes per year or $7,800….you just saved $4200 per year.

For Cummins 6BT/6BTA, KTA and QSK plus CAT 3500

USA sales@dieselcraft.com

West Coast: 530-613-2150

East Coast: 772-215-8087

Gulf Coast: 337-277-5417

Recent Comments