Customer Video:

Explanation #1:

Explanation #2:

Dieselcraft is the leader with over 50 years experience in the design and manufacture of industrial centrifuges.

Our centrifuges are used in a variety of settings across various industries including industrial, commercial vehicles, agricultural and marine. They all cut the cost of oil changes by 30% or more.

ALL solid particles above 1 micron are permanently removed from your oil

Let us help you with some mathematics and your Return on Investment.

If your oil change cost you $300 each and you do four changes per year, that is $1200 based on 100 miles per day driven and changes at 6-7,000 miles. Now extend oil life by 33% and changes are at 9,000 miles. You reduced changes to 2.6 per year or $792….you just saved $408 per year per truck.

Less oil and less filters to deal with.

We are waiting for you to contact us and we will show you proof that you can increase oil life…….do not procrastinate, contact us now.

Your standard oil filter does not catch most of this soot!

According to the SAE, particles as small as 4 microns can cause up to 77% of engine wear.

Today’s engines have what is called a full-flow oil filter. These filters generally filter to 25 microns.

A 25 micron filter is only 80% effective, meaning 20% of particles smaller than 25 microns are NOT held in the filter and go out to wear out your engine.

The Dieselcraft Centrifuge cleans engine oil by generating a centrifugal force which is 2,000 times greater than gravity.

Engine oil pressure spins the rotor.

That force separates the solid contaminates from the main oil supply while slinging the solids to the inside walls of the rotor, which is easily cleaned.

Contaminant particles less than 1 micron are removed, eliminating the wear on close tolerance metal parts.

After the oil pressure spins the rotor and removes the solids from the oil, the oil pressure is zero so the air pump puts 3 psi of air pressure into the centrifuge body to force the oil back to the engine.

The Dieselcraft Centrifuge remove dirt and wear particles from the oil flow altogether and remains constant, whereas filters take out solids and hold them from circulating further, but plug, reduce oil flow, and eventually reach the point of not working. In engine applications, oil change intervals using conventional oil can be extended 30-50%.

Comes with a 50,000 mile warranty.

- For Light, Medium Duty and Pick-up Trucks

- Model OC-25-Universal for ALL Duramax, Dodge Cummins12-24 valve, Ford 6-7.3 and more

New Price…Sale Ends Soon…. Now Only $559.

Over $100 less than the filter type bypass systems and no more special filters to purchase.

The complete kit includes the centrifuge, mounting plate, fitting kit, auxiliary air pump and hose.

99% Efficiency at removing oil contaminants down to 1 micron.

Pay with any credit or debit card.

Ten Benefits we can list for using a 1 micron oil centrifuge….can you name one for using your filter!

1. Cleaner oil, GUARANTEED

2. 30-50% longer oil life

3. Longer service intervals

4. Reduces engine wear

5. Long-term preventative maintenance

6. Reduced maintenance costs

7. Cuts waste disposal costs

8. Supports engine technology for the reduction of exhaust emissions.

9. Reduces total cost of ownership

10. Helps ensure clean combustion and fuel efficiency

Download Complete Centrifuge Install Data

Paper Filters

You have an engine in a vehicle or a vessel or generator in an application that is worth $20,000 or maybe $200,000 and you are protecting it with a $8 paper filter?

During this 12,500-mile interval, more than half a pound (8.5oz) of soot could enter the oil.

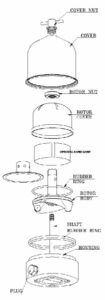

Cleaning the Dieselcraft Centrifuge

CAUTION: Hot oil can be dangerous and may burn the skin. Wear proper protective clothing when working with hot engine parts and hot oils. Avoid unnecessary skin contact with oil.

The Dieselcraft Centrifuge is very simple. It does not require any expendable parts or filters.

At every service period, you just have to open the centrifuge rotor, remove all dirt collected in the rotor then re fit the rotor and centrifuge cover.

- Unscrew top nut and remove the centrifuge cover.

- Lift the rotor completely off the shaft quickly and allow it to drain into an appropriate container.

- Prepare to unscrew rotor nut. Place the rotor, nozzles down over a 1-2” wide wooden block. You will see the block will stop the rotor from turning. Unscrew the rotor nut. The rotor nut should not be opened by hand.Unscrew it with a small adjustable wrench. Never grip the rotor nut tightly in clamping device like a bench vice. It may damage the rotor body permanently.

- Remove rotor cover by use of a RUBBER MALLET. Hold the rotor in one hand by gripping the cover so the rotor nut shaft is UP and tap the shaft lightly. This will cause the two part to separate. DO NOT USE A HARD FACED HAMMER. The top bushing can be damaged if hammered on.

- Remove the deflector that is under the cover.

- Remove the dirt collected from inside the rotor cover by the use of a plastic or dull metal scraper. Clean all the rotor parts thoroughly.

The dirt removed from engine oil is considered Hazardous Material. Dispose of it in the proper manner based your the laws of your county or state.

Re-Assembly

Always ensure that the arrow marks on rotor cover and rotor are matched after assembling the rotor. The rotor body is dynamically balanced. Mismatch of arrow marks on rotor cover and rotor will result in excessive vibration.

Do not over tighten the top nut. Snug plus 1/2 turn is all that is needed. Over tightening top nut will damage the centrifuge permanently.

Do not drop, hammer upon, distort or force during disassembly or reassembly. You may damage the device and void the warranty.

Recent Comments